"We are interested in GRC, FRP/GRP, PREFAB products/services, kindly get back to us with more details."

+91 96547 27964

CALL NOW +91 9824972266

Practicing

Since 1999

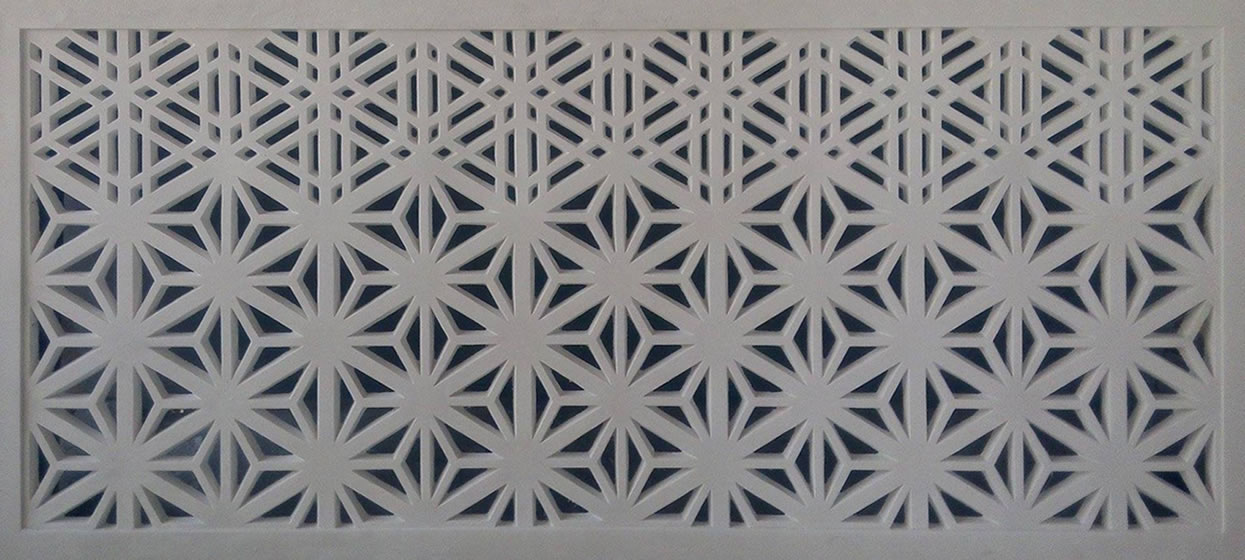

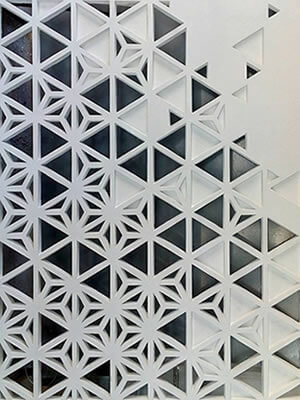

SWASTIK GRC & FRP Componants is a group of dedicated experts with a goal of providing high-quality GRC/GFRC jali solutions. As a prominent GRC jali manufacturer, we are committed to consistently enhancing our design, planning, and manufacturing capabilities. Our focus extends beyond creating perfectly designed GRC wall cladding panels. We also keep a close eye on the latest trends in GRC jali and molding patterns. Our GRC wall jali products are suitable for both indoor and outdoor applications, as they are built to withstand harsh climatic conditions. At Swastik GRC and FRP Componants, we offer a wide range of designer GRC jali, modern GRC jali, square shape GRC jali, decorative GRC jali for home, GRC panels, GRC moldings, GRC cladding and more which are available in various designs and sizes at affordable rates.

Glass Reinforced Concrete also known as glass fiber or fiberglass reinforced concrete (GFRC/FRC), is a highly versatile building material that has gained popularity in the design and pattern industries. GRC is a composite material composed of cement, fine aggregates, water, chemical admixtures, and alkali-resistant glass fibers. Our GRC products adhere to international standards established in Europe, America, Asia, and Australia. As a reliable GFRC jali manufacturer, we offer an extensive range of GFRC jali products with various colors, shades, and surface finishes. Our collection includes top-notch shapes and finishes that mimic natural stone, providing exceptional aesthetic appeal and quality.

Faster installation & savings in superstructure and foundations

Hard and dense surface offers resistance to graffiti

Minimizes breakages during transportation and erection.

Low maintenance & never rots or corrodes

Plain White & Natural earthen colours can be manufacture by adding pigment on mixed design. Plain smooth & acid wash finish(Stone Finish). GRC can be painted with any available colours manufacture by paint companies

So, no electromagnetic interference with signaling cables

AR glass fibre is irrespirable unlike asbestos fibre

Drying fixed with M.S. fixtures/Stainless steel

Can be Plain, Textured, Curved or with Bands

Along being excellent for reproduction and renovation, GRC offers amazing noise insulation property at lower frequencies. Stiffeners enhances the noise bearing efficiency. GRC with 10 mm thickness and 20 kg/M2 surface mass will reduce noise to about 30 decibel.

GRC possess outstanding tensile strength and long lasting lightweight structure against RCC which is heavy and weak in tensile strength. This greatly reduces the overall load on the building.

An understanding of practical design and complex modeling helps in determining the underlying cost of the whole project. As GFRC moulds are rigid and less-expensive they are best for reproducing intricate details and smooth sweeping curves in budget. For detailed undercuts expensive rubber mould liners may be required. The design and size chosen would affect the cost factor. GFRC can be cast in pieces up to 12’ in length; for longer length pieces can be joined. We recommend pieces of maximum 60-80 sq ft area as it is difficult to handle and ship long GFRC castings.

There are four ways of sealing joints in GRC components and panels. Gasket and open dained joints are susceptible to climatic changes. This can create weak points that can eventually affect weatherproof seal of the component. Third way is to use Cover Strips. Theoretically it can be a good alternative but practically they are not acceptable. The intersection of the vertical and horizontal cover strips makes it impossible to maintain weather tightness. Last but not the least comes Sealants. Sealants such as silicone/PU are used with proper care. The success of the sealant depends upon the primer. All of our products are manufactured with utmost care with good joint design. We also guide our clients whenever they need our consultation.

Maintaining GFRC is not a rocket science job as you can easily remove dirt or stains with common household cleaners. With time GFRC components may get chips and damaged edges which will demand instant repairs to avoid further damage. Properly done cleaning and repairs will further increase the life of the product. To keep the GFRC component in a good state it is advisable to follow GFRC patching institutions given by us.

The success of any GFRC system depends on a coordinated effort by the designer, manufacturer and installer. Sequence, deliveries and manufacturing tolerances are critical to the success of the project and should be mutually agreed upon by all parties. Submittals and shop drawings should be utilized extensivelyto familiarize the designer and installer with the method of attachment, reinforcement and fabrication. This process alerts the designer to any possible conflicts. The GFRC shop drawings should be complete in every detail to allow the installing contractor a complete inventory of parts and pieces, as well as expected tolerances.

GRC is a versatile building material with a special demand in Architect and Designing sector. The concept behind replacing RCC with GRC is to give quality as well as flexible design orientated approach to the market. Rightly manufactured and installed GRC system provides an innovative and aesthetically pleasing appearance. Design and strength come hand in hand at best affordable rates. GRC comes with effortless installation and uninstallation so it requires less on-site labour, hence, reducing further cost.

| PROPERTY | UNIT | MACHINE SPRAY |

|---|---|---|

| Glassfibre (AR) | (WT.%) | 2 to 5 depending upon component of GRC |

| Flexural Strength | Mpa | 6-11 |

| Compressive Strength | Mpa | 35-65 |

| Impact Strength | Kj/m2 | 7-20 |

| PROPERTY | DETAILS |

|---|---|

| Thickness | 12 to 15mm (depending upon article) |

| Wt./Sq. Ft. | 2 to 4 kg (depending upon article) |

| Dry Density | 1.8 to 2.2 T/M3 |

| Colour | Any earthen colour (popular colours are White & Pink) |

| Texture | Plain Smooth Finish, Painted, Acid Wash (Stone Finish) |

"We are interested in GRC, FRP/GRP, PREFAB products/services, kindly get back to us with more details."

+91 96547 27964